Tuesday, November 12, 2013

Machining materials are chosen based on a variety of factors. The first and most important factor to consider is whether a material will fit the needs of the part. Questions of durability are considered, given the expected purpose and working environment of a given machine part. Of course, different materials have different strengths and weaknesses, and price can always limit available options.

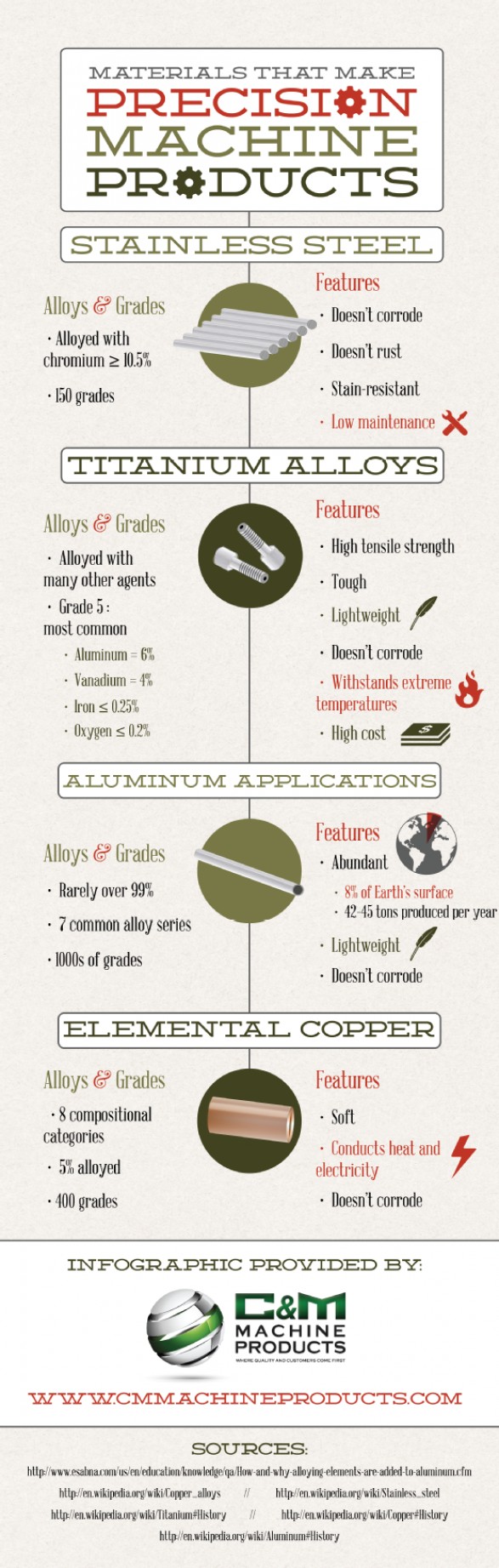

Stainless steel, for example, is unique for its longevity and low level of required maintenance. It doesn’t rust, and it’s stain resistant.

Aluminum applications and titanium alloys are two machining options that are both lightweight, but very different in other respects. The supply of aluminum is high, as it comprises 8% of the surface of the planet. Titanium alloys, on the other hand, are extremely tough and resistant to high temperatures, but not without a high price point.

The fourth machining material featured in the image below, elemental copper, is used in applications that require the conduction of electricity and heat. Other machining options include metals like brass and bronze. With the abundance of options available to machine shops, businesses like Lowrance Machine Shop can provide high quality custom parts that are perfect for any given job.

TAGGED AS:

- machining

- machining materials